Recipe

Preparing

- Before starting work, disinfect all surfaces and utensils that may come into contact with milk.

- Determine if the milk is suitable for cheese making. It must go through the bactericidal phase (usually, cooled milk from the previous day is fine). If you have a pH meter, the milk pH level should not be outside the pH 6.55-6.85 range (which is rare). After pasteurization, the acidity of milk can increase rapidly (the pH number becomes lower). In this particular recipe, milk with a pH of 6.60 was used after pasteurization and cooling.

- Pasteurize the milk: heat it to 65C and hold it at this temperature for 30 minutes. You can also heat it to 70C and hold it for 15 minutes.

- Rapidly cool the milk, for example, in a cold bath to 32C (this may take 15 minutes).

|

Processing

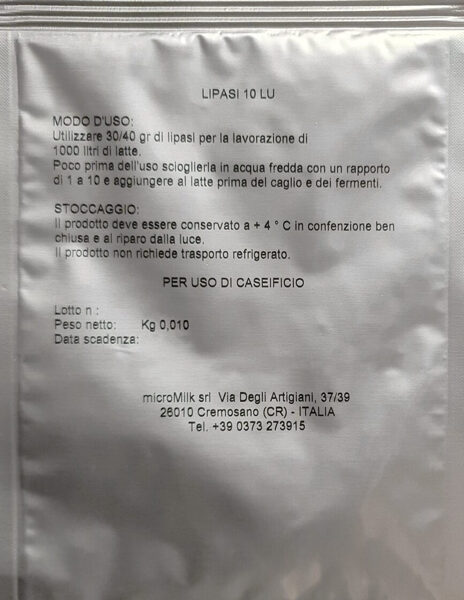

- Add the cheese culture Micromilk LHR/A 0.6 grams and lipase 1.2 grams.

- Wait 5 minutes and stir the cheese culture into the milk.

- Add calcium chloride 2.5 ml, annatto 10 drops, and rennet 1 ml. Stir into the milk for 30 seconds, cover, and leave it for 60 minutes. Calcium chloride and rennet must first be diluted with 50 ml of clean water before adding to the milk.** Calcium chloride and rennet must be added separately.

- After 60 minutes, a very firm curd should form. When you insert and turn a knife into it, no curd particles should remain on it.

- Start the cutting process. Cut with a 1.5-2.5 cm gap both vertically and horizontally. Do not stir!

- Leave it for 90 minutes.

- Now you can stir and use a knife or spatula to help separate the previously cut cubes from each other.

- Increase the temperature to 53°C (127°F) over 30 minutes and stir every 5 minutes to prevent the cubes from sticking together. The hotter the mixture, the more often you need to stir.

- The cubes should be reduced to the size of coffee beans.

|

Pressing and salting

- The total pressing time is 10 hours and 30 minutes. Although there is no particular order to how often you turn the cheese and increase the weight, here is one example of a process you can follow:

- First press: 30 minutes (weight should be enough to drain the whey through the mold)

- Second press: 2 hours (turn the cheese and increase the weight)

- Third press: 8 hours (turn the cheese and increase the weight)

- The salting time is 12 hours in the refrigerator. After 6 hours, turn the cheese over for even salting.

- After salting, the cheese should be dried with paper towels and placed to dry at room temperature for 1-2 days on a mat.

- The cheese is not intended for long-term storage, but if it has dried well at room temperature for 3-5 days, it can be covered with a protective coating, wax, vacuumed, or washed and greased with oil more often (as you prefer).

|

We look forward to your feedback!

* Freshly milked milk has bactericidal properties for a few hours, during the so-called bactericidal phase, when bacteria suppress reproduction. Cooling the milk prolongs the bactericidal phase. If the milk is obtained in strict compliance with sanitary regulations and rapidly cooled to +40 °C, the duration of the bactericidal phase is 24 hours and more. At the same temperature bactericidal phase period, impure milk has at least two to three times shorter temperature. The duration of the unrefrigerated milk phase is, on average, 2 hours.

(Source: http://www.ezerzeme.lv/lv/zinas/noderigi/5222/par-piena-kvalitati)

** The time of milk coagulation (thickening) depends on the quantity of calcium chloride and rennet. It can be adjusted for best coagulation time, which should ideally be 12 minutes. For instance, if the first time your milk has thickened after 20 minutes, then increase the next dose of enzyme.

*** During pressing, the cheese releases whey and also increases the level of acidity, which is an important regulatory process in bacteria. If you slightly increase this pressing time, then it will be easier to melt the cheese. Such cheese is perfect for hot buns or in pizza making. If the pressing time is too long, it will lose its elasticity and become fragile.